What are the reasons for using aluminum profiles in the equipment frame?

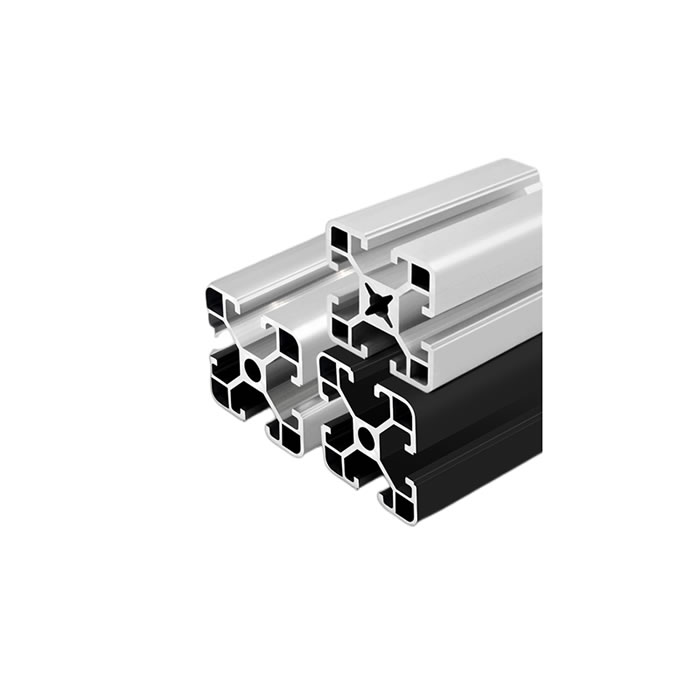

Industrial Aluminium Profile is an alloy material mainly composed of aluminium. Aluminum rods are extruded by hot melting to obtain aluminium materials with different cross-section shapes. However, the mechanical properties and application fields of industrial aluminium profiles are different due to the different proportion of alloys added. Industrial aluminium profiles have a high cost-effective ratio in terms of price and material. Their essence is light weight, high strength and strong corrosion resistance. In addition, they have their own silver anode oxide color and are easy to install, which also conforms to industrial working conditions. Equipment frame is made of industrial aluminium profiles. Basically, all kinds of machine and equipment frames used in the factory are supported by profiles. Because the plant production equipment is upgrading and the manufacturers are increasing the equipment frame, what are the reasons for using aluminium profiles in equipment frame?

The equipment frame is made of industrial aluminium profiles and can be introduced from three points:

1. Functional characteristics of profiles

The light weight, high strength and high density are only 2.7g/cm3, about 1/3 of the density of traditional metals such as steel, copper or brass. With strong shaping and wide application, the corrosion resistant surface is easily maintained and maintained by silver oxide (black) anodized, which can be connected with any auxiliary product for a long service life.

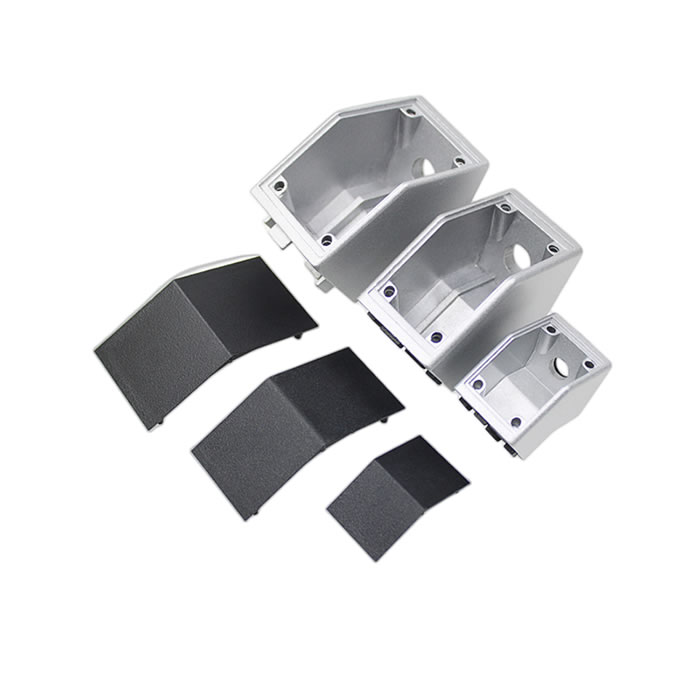

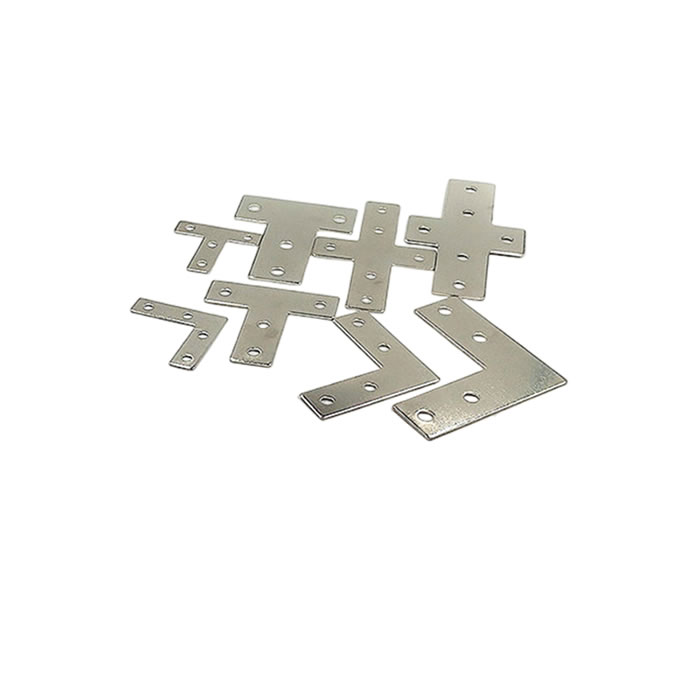

2. Easy assembly

The modular assembly system can be disassembled and assembled arbitrarily, and can process profiles in various ways. Two or more profiles can be assembled into a frame by using accessory bolts and nuts. It can be assembled manually by itself with strong and stable strength.

3. Short delivery period

If the Customer has drawings directly purchasing the required profile, the manufacturer can ship the same day by dimension cutting. If the frame structure is complex, various processing services are required. Negotiation with the merchant can be done on the same day if time and order permit. It may take 1-2 days for the manufacturer to assemble the finished product. Arrange according to the total quantity.