CNC Aluminum Machining - High Precision and Complex Parts Expert

Welcome to the CNC Aluminum Machining page for SAIVS! We specialize in manufacturing non-standard precision aluminum parts with complex structures, ensuring high accuracy and reliable components. Our services include aluminum CNC prototyping, custom aluminum part manufacturing, and advanced 5-axis CNC milling for various industries.

Key Benefits:

- Lightweight yet strong - ideal for various applications

- Excellent machinability and corrosion resistance

- Greater electrical conductivity and low-temperature resistance

- Wide range of surface finishes and anodization options

- Lower production costs and recyclability

Machined Aluminum Prototypes

Before mass manufacturing, aluminum CNC prototyping is an effective way to handle complex design verification and pre-production testing. Our efficient, accurate, and cost-effective in-house process delivers superior product results that address your unique requirements and constraints. With our pool of skilled engineers, we ensure you receive the most effective machining processeses for your budget, time, and materials.

Manufacturing Custom Aluminum Parts

Looking for expert help on your custom aluminum projects? At SAIVS, not only are we a highly capable and affordable production source, but we also commit ourselves to excellence in technology, experience, and skills. With our ISO9001-certified quality system, efficient production processes, and adaptable custom engineering, we deliver complex projects quickly and with excellent product quality.

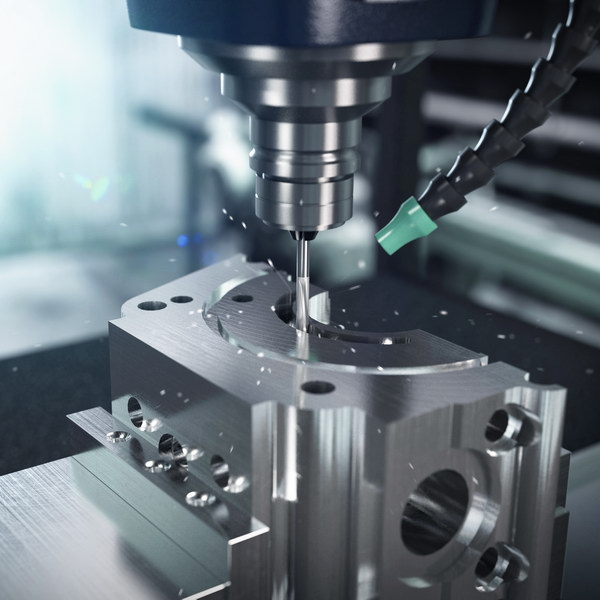

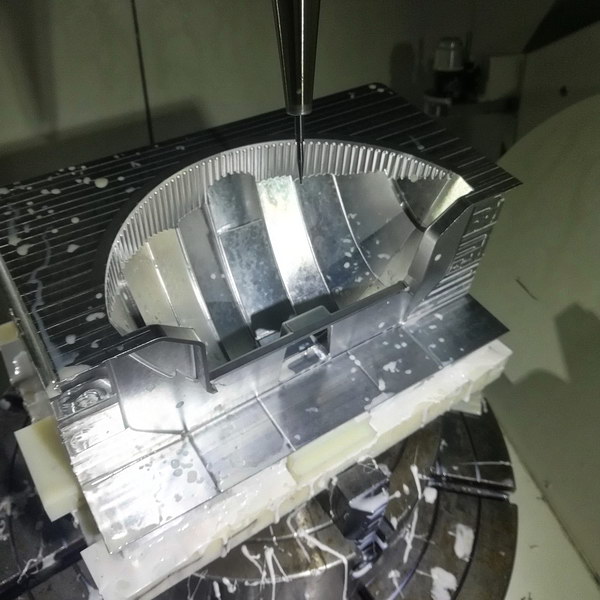

5-axis CNC Milling Aluminum

Our 5-axis CNC milling capabilities significantly expand the range of possibilities for machining complex aluminum parts. We can meet your most challenging manufacturing requirements with high precision, tight tolerances, and excellent surface finishes – all in a single setup. The benefits of 5-axis milling include increased machining productivity, higher accuracy, outstanding surface finish, and lower fixturing costs.

Dimensional Stability in CNC Aluminum

We follow these steps to improve dimensional stability in CNC aluminum:

1. Eliminate internal stress of the material

2. Improve the clamping method of the workpiece

3. Enhance cutting tool capabilities

4. Choose a reasonable machining process

5. Use appropriate operation methods

Integrated Machining Process

Our aluminum CNC machining isn't a standalone production process. We integrate 3-axis, 4-axis, and 5-axis CNC milling, CNC turning, and other manufacturing techniques to create a more efficient and cost-effective process. Our process combinations include various technologies like EDM, wire EDM, die casting, investment casting, aluminum extrusion, and forging.

Ready to start your CNC Aluminum Machining project? SAIVS is your go-to expert for all things CNC aluminum machining.