Reasons and Solutions for the Loosening of Industrial Aluminum Profile Bolts

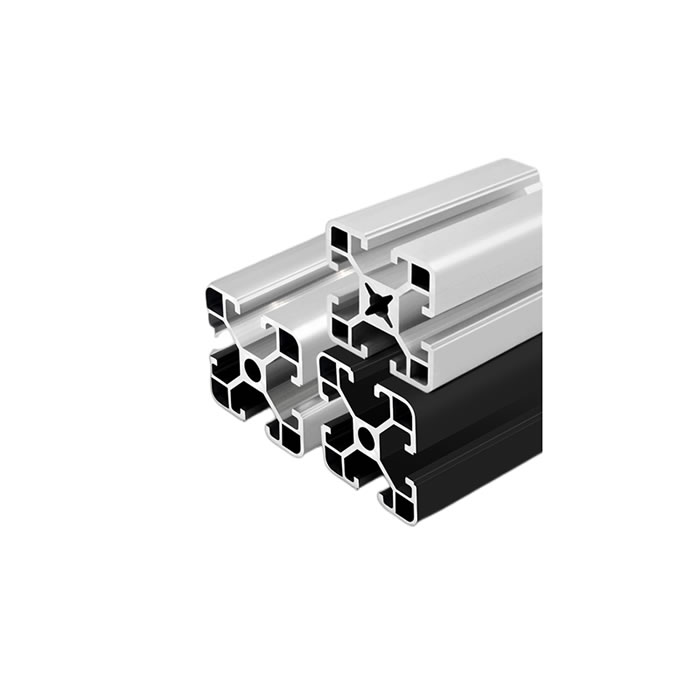

Industrial Aluminum Profiles are widely used in construction, transportation and various other industries.

One common problem that arises during the use of industrial Aluminum Profiles is loose bolts.

Loose bolts can cause a wide range of issues, from reduced structural integrity to malfunctioning of machinery.

In this article, we will take a look at the reasons for loose bolts in industrial aluminum profiles

and provide effective solutions to prevent this problem from occurring.

Reasons for Loose Bolts in Industrial aluminum profiles

Insufficient Tightening Force

One of the most common reasons for bolts becoming loose is a lack of sufficient tightening force.

This can occur due to poor workmanship during the installation of the bolts or due to the use of low-quality tools.

In addition, when aluminum profiles are exposed to changing temperatures,

they may expand or contract, which can result in a loss of tightening force.

Vibration

Industrial machinery, vehicles and other equipment that use aluminum profiles may generate vibration,

which can cause bolts to gradually loosen over time.

This can happen particularly in situations where the equipment is subjected to significant shock or impact.

Wear and Tear

Aluminum profiles are typically subjected to harsh environmental conditions,

which can cause the metal to degrade over time. When bolts are exposed to corrosion,

the surface of the threads can become rough, which can cause the bolts to loosen up and ultimately fall out.

Improper Installation

Improper installation of bolts is another common reason for loose bolts in industrial aluminum profiles.

Bolts that are placed too far apart or not installed at the correct angle

may not provide enough support to hold the aluminum profiles in place.

Solutions for Loose Bolts in Industrial Aluminum Profiles

Proper Tightening

To prevent bolts from becoming loose due to a lack of tightening force,

it is important to ensure that the bolts are tightened correctly.

This can be achieved by using high-quality torque wrenches and ensuring

that the fasteners are tightened to the correct torque specification.

Use of Thread Lockers

Thread lockers are specially formulated adhesives that are designed to keep bolts in place.

They work by filling the gaps between the threads of the bolt and the nut,

which helps to prevent vibration from causing the bolt to loosen up.

Thread lockers come in a variety of formulas,

and it is important to choose the right type for the specific application.

Regular Maintenance

Regular maintenance of industrial aluminum profile systems

can help prevent bolts from becoming loose due to wear and tear.

This includes cleaning the profiles and hardware and inspecting the bolts for signs of corrosion and damage.

Any bolts that show signs of wear and tear should be replaced as soon as possible.

Proper Installation

Proper installation of bolts is crucial to ensuring that the aluminum profiles stay securely in place.

This includes ensuring that the bolts are installed at the correct angle,

with the right spacing and in accordance with the manufacturer's specifications.

In summary,by understanding the reasons for loose bolts and implementing effective solutions,

can ensure that industrial aluminum profiles remain secure and provide reliable performance over the long term.